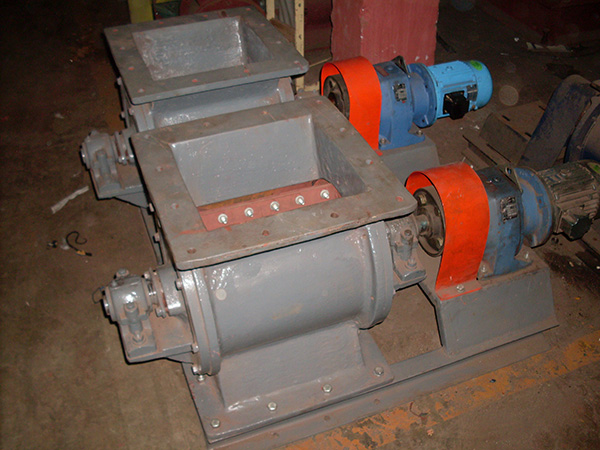

Rotary Airlocks Standard Features

Rotary Valves are used throughout industry, wherever precision volumetric feeding is required. Many standard models, types and sizes are provided as per your specification & requirement. Because of our years of experience in developing, testing and specifying rotary valves, we can help you choose the right valve for any application.

Heavy - duty valve bodies made of cast gray iron or stress relived steel welds for pressures to 15 PSI. Valve rotors are precision machined to match their bodies, with standard clearances of .004" +/- .001" (or to your specifications). Extra thick cast gray iron end plates are precision fit into the body bore for support of bearings and seals without distortion. Fabricated steel rotors with 8 blades, 1/2" thick for strength and slightly canted to reduce shear load. Some models come with heavy-duty cast ductile iron rotors, which are specially designed to reduces shear load. Special materials, design and replaceable tips are available. Flanged stock inlet - square standard, round optional. Adjustable scraper blade or brush option- al with square inlet. Triple bearings protection on inboard bearings models - (1) rotor hub seal plate (2) double lip seals (3) a packed labyrinth. Permanently lubricated bearings are standard on inboard models. Re-lubricat- able bearings and packing gland seals are used on outboard bearing models.

Shafts are keyed on both ends, for motor mount flexibility. End opposite drive is protected with shaft guard.

Parallel shaft gear motor drive with adjustable base. Whenever a drive is ordered, we provide this superior type drive as standard. Totally enclosed sanitary chain guard is provided with optional gear motor drive.

Air lock feeders

Rotary Air Locks and Feeders are usually used to accomplish 3 basic tasks :

- To feed material from bins or hoppers.

- To deliver fines from the collector while sealing against sir loss.

- And to feed material to pneumatic conveying line against pressure.

DUSOL TECHNOLOGIES Rotary Air Locks are built to work under a variety of conditions. Three basic designs cover the tasks described above.

Drop thru type

This is for gravity discharge of materials from storage hoppers and bins into receiving equipment or conveying lines.

Side entry type

This design, specially developed for plastic handling and friable granular materials which tend to disintegrate while handling in conventional rotors, finds extensive application in the industry. This design is accompanied with deflector plates and beveled and rotor plates.

Standard rotor

This a standard rotor with replaceable bars of steel, brass or Teflon or any other materials suiting the application. This is used where excessive wear of rotor edge is anticipated. These Valves are suitable for most dry dust such as Chemicals, Coffee, Detergents, Dry foods, flour. Grains. Plastic, Starch, and Sugar etc. Rotary Valves manufactured by DUSOL are used as metering devices feeders and rotary locks for dry free flowing materials of varying size shapes, used with blenders, mixers, tanks, silos, classifiers, dryers, collectors, hopers, cyclones collectors, in virtually every industry.