Project Engineering & Management

Dusol technologies promote a healthier Industrial world by being one of the largest supplier of Filter bags for all Industrial applications. Our associate Dusol technologies plant was designed and developed under the guidance of BWF Textil GmbH Co. KG, Germany, BGF Industries USA and various machinery manufacturers. They are the recognised filter bag suppliers to major OEM's in India at large. Our endeavour is on the path of developement and expansion bringing to you the latest fibers and needling technologies.

PRODUCT RANGE AND ITS APPLICATION

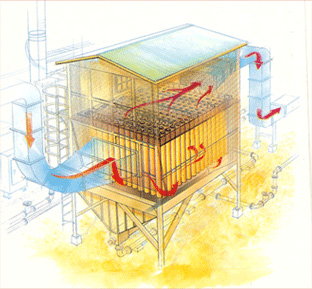

Our filter bags are manufactured both from woven and non-woven needlefelts of Polyester, Polypropylene, Polyacrylonitrile, Acrylic, Nomex Ryton, Tefair, Teflon, Fibreglass for its application in mechanical shaker units, Reserve & Pulse jet systems.

The conventional shaker system which are still in use in few bag houes where woven cloth of 250 gms to 350 gms/m2 are utilised.

Filter bags of woven Fibreglass comes with Silicone, Graphite, Teflon and acid resistant polymer treatments. They are available from 250 gms to 650 gms/m2 for its application in pulse jet and low ratio bag houses.

THE DRAMATIC INNOVATION:

The advent of needlefelts has brought a dramatic change in the filtering systems. They are a three dimensional filter media filtering both on the surface and in the depth.

The needlefelts contain an internal supporting woven fabric which account for high tensile strength, flexibility, low elongation and reliable dimensional stability. The high pore volume and density has enhanced the collection effeciency even at a higher air to cloth ratio. Hence a reduced filtering area resulting in cost effectiveness.

Depending on the properties of the dust, dust contents of clean gases below 10 mg/m3 can be achieved. Needlefelts can be chemically treated for special applications. They are available from 350 gms to 650 gms/m2.

| Quality | Application | Resistant to | |||||

|---|---|---|---|---|---|---|---|

| Acids | Alkalis | Temperature .c | Hydrolysis | Organic Solvents | |||

| Cont. | Peaks. | ||||||

| POLYESTER | Cement Industry & Refractories,Asbestos Ind., Iron & Steel Plants, Wood Ind., Plastic & Pigment, Aluminium (Normal application under dry conditions) | 1 | 4 | 150 | 150 | 5 | 3 |

| POLYPROPYLENE | FOOD INDUSTRY (Flour, Milk powder) Detergent Industry. | 1 | 1 | 90 | 95 | 1 | 4 |

| ACRYLIC (copolymer) | Lime, Cement Plants, | 2 | 3 | 115 | 120 | 2 | 3 |

| POLYACRYLONITRILE(Homo-polymer) | Cement Industry, Asphalt Factories , Spray Dryers, Lime. (Application under humid conditions) |

2 | 2 | 120 | 125 | 2 | 3 |

| NOMEX (aromatic Polyamide) | Asphalt Plants, Iron & Steel, Cement & lime Ind., Metal alloy, Smelting Plants, Ceramic Industry. |

2 | 2 | 180 | 200 | 3 | 1 |

| RYTON (Polypheny - lenesulifide) | Coal fired Boilers (fluidized Bed and PC) Chemical Industry. (Application at elevated chemical & hydrolytical attacks) | 2 | 2 | 170 | 190 | 1 | 1 |

| TEFLON(Polytetrafluor ethylene) | Carbon Black Industry, Lignite & Coal fired Boilers (Stroker), Refuse Incineration, Chemicals, (All application with extreme chemical attacks) | 1 | 1 | 260 | 280 | 1 | 1 |

| Fibreglass | Carbon Black Industry, Cement Industry, Electro – Smelting Ovens. | 2 | 3 | 200 | 260 | 2 | 2 |

FILTER BAGS FOR ALL DE-DUSTING SYSTEMS WITH ALL POSSIBLE METHODS OF DE-DUSTING

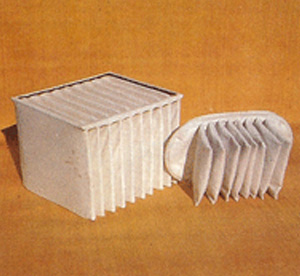

FILTER CARTRIDGES & POCKETS

MULTI-FILTER POCKETS FOR SMALL DE-DUSTERS AND FOR SILO FILTERS

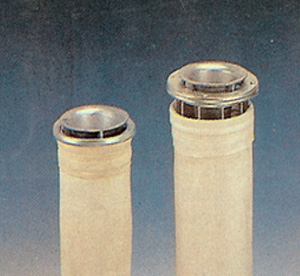

FILTER BAGS