Dust Collector

Dusol Technologies Offer two dust collector, either top entry or hopper entry, depending on your particular needs. Top entry is the most effective design for fine dust. Since the air flow is downward, it aids the migration of fine particulate towards the hopper. Hopper entry is the proven choice for coarse, heavy dust and high dust loads, which require air -to-cloth ratios of 6:1 or less. Heavy particulate naturally move downward to the hopper. Our dust collectors are designed bag removal and a construction consisting of a top plenum, housing and hopper section. No matter what the design, these marks of superior craftsmanship remain constant.

Dust Laden air enters the unit through a high inlet designed to reduce upward internal velocities which are prevalent in bottom entry collectors. Dusol technologies Dust Collectors designs have improved the high inlet by incorporating a dropout section and perforated baffle plate causing velocities to be lowered at the entry to the collector. This feature allows heavier mass dust particles to drop out into the hopper and reduces the amount of dust carried to the filter media. Controlling velocities and direction of air movement within a dust collectors are very important to the efficiency of the unit as they reduce re-entrainment of dust.

Dusol's Dust Collectors patented cleaning mechanism generates a short powerful burst of induced air flow into the top of the bag. These bursts reverse the air flow momentarily flexing the fabric bags to knock off excess dust agglomerated on the top layer of the filter cake while maintaining a functional filter cake. The purge tube with patented high velocity nozzles is positioned directly over the openings at the top of the bags. Each purge tube is connected to a large fast at the top of the bags. Each purge tube is connected to a large fast acting diaphragm valve are pneumatically operated and actuated by direct acting solenoid pilot valves, controlled by an adjustable electronic timing panel.

The patented high velocity nozzle allows Dust Collectors to eliminate the venturies used in most generic pulse-jet collectors. Venturies can restrict filtering velocity, impede cleaning, and cause puffing and abrasion around the top of the bags. With the patented high velocity nozzle, our cleaning system is able to use higher air-to-cloth ratios and less compressed air while inducing more air per cubic foot of compressed air than plain orifices, conventional converging nozzles, or straight nozzles.

Clean Air Section

it contains bag holding plate,inspection cover and outlet of bag filter.Precision cut bag -holding plate provided for high accuracy and perfect bag fixing. The above style of accurately cur tube sheet is taken for avoiding many of the related aspects which will later on effect the trouble free working of the filter bags. Few of the points which help us in getting better efficiency are like there is complete sealing of the filter bags thus avoiding any kind old leakage of dust which inwardly effects the differential pressures of the dust collector unit. The other major factor that is the alignment of the cages is maintained with the alignment of the filter bags. The above type pulse nozzle pipe considered which is bound by unison bolt on the other side reduces the time of removal and installation of bags.

The above firing pipe is such precisely engineered so as to come to automatic alignment with the filter bags for accurate operation and trouble free working. Dusol also takes further care from its varied experience in the industry by giving the provision of the engineered universal venturie which provides best support to the principle of de-dusting of the filter bags.

Filter Bags

That filter bags form the heart of the system and it is where we have given our most prominent emphasis, these bags are very well taken care from the time of the procurement of the base fibers to the ultimate manufacturing of the base fabric and then to the complete unit as filter bags.The selection of fiber is made from both India and abroad .In terms of the foreign fibers the best of the fibers are selected which are the alpha fibers . They are then compiled and formed into twisted strands to the ultimate composite threads and formed to scrim which is designed as per the demand of the situation which can be a combination of the various weaves and patterns of the textile industry.These in turn control the well specified emission level which only and only dusol can guarantee in this Indian sub-continent.

The benefits offered from the filter bags of Dusol Technologies are:

- Lower stack emission levels,lower to the rate less than 25mg/m3.

- Lower pressure drop levels for better and efficient working.

- Better collection at the hopper in turn meaning better energy utilizations and lower maintenance costs.

- A free hand concept of installation of the filter bags incorporating the snap band.

- The snap band concept in turn acts as a dual device, which on one hand provides complete sealing of the clean air chamber and also an efficient locking device for the bags and the cages from falling into the hopper.

- The selections of the special fibers that pose and exhibit the quality of perfect elastics and henceforth give efficient dust disposal capabilities.

- The use of the modern chemicals also comes to rescue by providing various properties like charge neutralization, reduced emissivities,increased conductivity, moisture control,better cake releasing properties and what not at the cost of peanuts.

- The fabrics are made in unison with closely monitored stitching which gives a three layered pros to the user. 1.Better strength to the fabric during the time of the over excessive purging and blindness of the fabric. 2.A closed pore concept allowing the least valuable leakages in the filter bags. 3.The better selection of the threads to make the filter bags immune from the clutches of industrial reactions and hazards.

- A better breaking strength.Elongation gradient and tearing strength which in turn makes the bag the most delicate but also the most robust part of the whole equipment.

- A coarser base fabric enables the heavier particle to fall off the fabric as it exhibits the unique quality. Dusol has experience and capability to manufacture cages and venturies for almost all bag house OEM's. Cages are available in two distinct styles - interlock and rigid wire

Rigid Wire Cages:

We manufacture rigid wire cages using extremely accurate robotics to make the spacer rings.Wire is pulled off a coil through a cutting die and around a coiling pin which forms the wire into an open ring.Welding jaws then grasp the ring and close the ends, applying pressure and introducing a precisely controlled pulsing current which then bonds the ends into a continuous ring.In a separate operation-, stringer wire is pulled off a coil through a straightening track and cut to precise lengths. These individual stringer wires are then loaded into a magazine which maintains the exact spacing of the wire. The wires are fed through the welding mandrill where the bottom pan is welded to the inside of the pan.

The wires then continue on through the welding mandrill where the spacer rings are attached using the latest technology in computer controlled multi- pulse resistance welding. The top component is fixture welded to the tube to maintain finished cage length and assure proper alignment as the cage hangs in the bag house.

Interlock Cages:

Dusol's Interlock Cages are made from 12 gauges welded wire mesh that is formed into a tube by a fully automatic tubing machine.As the edges of the tube come together they are interlocked with a seam strip for strength and durability.This continuous tube is then cut into specific lengths up to 22 ft.long by a traveling blade. The top and bottom of each tube is then sized to fit the appropriate components.

New cages extend bag life:

Reduce unnecessary bag wear with our durable rigid cages designed to fit most OEM applications. Because we design and manufacture both high quality bags and cages, We offer an extensive selection of highly compatible diameter and components including custom manufactured cages and bags.

Our rolled flange top with integral venturie and rolled bead pan design prevents premature bag wear at important stress points.The results are bags that do the job better clean more easily and last longer. Also available is the unique two piece design that permits cage installation in areas with restricted headroom.

Additional Benefits:

- Ring wire welds are located inside the cage away from the bag to reduce wear.

- Long lasting galvanized tops, bottoms and wire the resist corrosion.

- Mild steel, 304 and 316 stainless available.

- Durable 4-7 mm wire construction.

- More rigid 150 mm ring spacing standard.

- A better standard strengthening by introducing 10-12 wires as standard.

- Various finishes are available to suit the specific need or application of the process.

- These include epoxy,PTFE coated, Polyuthane, pigment finish and many more.

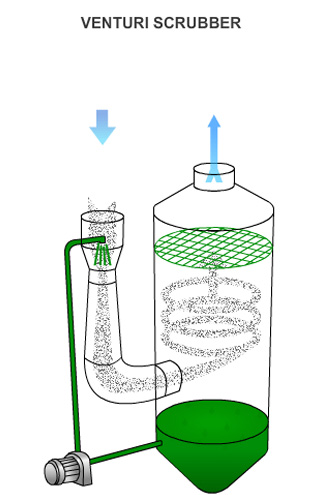

Venturie:

A Venturie is an integral component of some pulse jet collectors. It directs the blasts of compressed air into the center of the filter bag to prevent abrasion caused by misaligned blow popes and turbulent airflows. If venturies become damaged or worn,compressed air doesn't gain the velocity required to effectively clean the filter bags.

The venturie plays another vital role in protecting the delicate bags from getting disintegrated and lose their critical properties.They increase the filtering efficiency by delivering the right amount of compressed air required to clean the filter bags at every nook and carny.

We offer our customers a wide range of venturie for their specific needs and applications.The varieties range from very wide spectra such as:

- Aluminum pressure die cast design

- Aluminum sheet metal.

- Mild steel.

- Stainless steel.

- Mild Steel with grade IS 513,IS 2062.

- Nickel alloy mixed designs.

- Galvanized design.

- Epoxy or FRP lined.